Mechanical testing is carried out to produce data that may be used for design purposes or as part of a material joining procedure or oper...

Mechanical testing is carried out to produce data that may be used for design purposes or as part of a material joining procedure or operator acceptance scheme. The most important function may be that of providing design data since it is essential that the limiting values that a structure can withstand without failure are known.

Inadequate control of the material properties by the supplier, or incompetent joining procedures and operatives are, however, equally crucial to the supply of a product that is safe in use. An example of this dual role of mechanical testing is the tensile test that may be used either to determine the yield strength of a steel for use in design calculations or to ensure that the steel complies with a material specification's strength requirements.

Mechanical tests may also be divided into quantitative or qualitative tests. A quantitative test is one that provides data that will be used for design purposes, a qualitative test where the results will be used for making comparisons - hardness or Charpy-V tests - for example as a 'go/no go test' such as the bend test.

Mechanical property data are obtained from a relatively small number of standard tests and these will be covered over the next several articles. These will include tensile and toughness tests, the tests used for welding procedure and welder approval and those used for the determination of in-service properties.

Tensile Test - Turned Specimen (All weld metal Specimen)

As mentioned earlier the tensile test is used to provide information that will be used in design calculations or to demonstrate that a material complies with the requirements of the appropriate specification - it may therefore be either a quantitative OR a qualitative test.

The test is made by gripping the ends of a suitably prepared standardised test piece in a tensile test machine and then applying a continually increasing uni-axial load until such time as failure occurs. Test pieces are standardised in order that results are reproducible and comparable as shown in Fig 2.

|

| Fig.2. Standard shape tensile specimens |

Specimens are said to be proportional when the gauge length, L0, is related to the original cross sectional area, A0, expressed as L0=k√A0. The constant k is 5.65 in EN specifications and 5 in the ASME codes. These give gauge lengths of approximately 5x specimen diameter and 4x specimen diameter respectively - whilst this difference may not be technically significant it is important when claiming compliance with specifications.

Both the load (stress) and the test piece extension (strain) are measured and from this data an engineering stress/strain curve is constructed, Fig.3. From this curve we can determine:

a) the tensile strength, also known as the ultimate tensile strength, the load at failure divided by the original cross sectional area where the ultimate tensile strength (U.T.S.), σmax = Pmax /A0 , where Pmax = maximum load, A0 = original cross sectional area. In EN specifications this parameter is also identified as 'Rm';

|

| Fig.3. Stress/strain curve |

b) the yield point (YP), the stress at which deformation changes from elastic to plastic behaviour ie below the yield point unloading the specimen means that it returns to its original length, above the yield point permanent plastic deformation has occurred, YP or σy = Pyp /A0 where Pyp = load at the yield point. In EN specifications this parameter is also identified as 'Re ';

c) By reassembling the broken specimen we can also measure the percentage elongation, El% how much the test piece had stretched at failure where El% = (Lf - L0 /Lo ) x100 where Lf = gauge length at fracture and L0 = original gauge length. In EN specifications this parameter is also identified as 'A' ( Fig.4a).

|

| Fig.4 a) Calculation of percentage elongation b) Calculation of percentage reduction of area |

d) the percentage reduction of area, how much the specimen has necked or reduced in diameter at the point of failure where R of A% =(A0 - Af /A0 ) x 100 where Af = cross sectional area at site of the fracture. In EN specifications this parameter is also identified as 'Z', ( Fig.4b).

(a) and (b) are measures of the strength of the material, (c) and (d) indicate the ductility or ability of the material to deform without fracture.

The slope of the elastic portion of the curve, essentially a straight line, will give Young's Modulus of Elasticity, a measure of how much a structure will elastically deform when loaded.

A low modulus means that a structure will be flexible, a high modulus a structure that will be stiff and inflexible.

To produce the most accurate stress/strain curve an extensometer should be attached to the specimen to measure the elongation of the gauge length. A less accurate method is to measure the movement of the cross-head of the tensile machine.

The stress strain curve in Fig.3 shows a material that has a well pronounced yield point but only annealed carbon steel exhibits this sort of behaviour. Metals that are strengthened by alloying, by heat treatment or by cold working do not have a pronounced yield and some other method must be found to determine the 'yield point'.

This is done by measuring the proof stress ( offset yield strength in American terminology), the stress required to produce a small specified amount of plastic deformation in the test piece.

The proof stress is measured by drawing a line parallel to the elastic portion of the stress/strain curve at a specified strain, this strain being a percentage of the original gauge length, hence 0.2% proof, 1% proof (see Fig.5).

For example, 0.2% proof strength would be measured using 0.2mm of permanent deformation in a specimen with a gauge length of 100mm. Proof strength is therefore not a fixed material characteristic, such as the yield point, but will depend upon how much plastic deformation is specified. It is essential therefore when considering proof strengths that the percentage figure is always quoted. Most steel specifications use 0.2% deformation, RP0.2 in the EN specifications.

Some materials such as annealed copper, grey iron and plastics do not have a straight line elastic portion on the stress/strain curve. In this case the usual practice, analogous to the method of determining proof strength, is to define the 'yield strength' as the stress to produce a specified amount of permanent deformation.

To approve a butt welding procedure most specifications such as BS EN 288 Parts 3 and 4 and ASME IX require tensile tests to be carried out.

Tensile Test - Square or Rectangular cross section (Transverse Specimen)

These are generally cross joint (CJ) tensile tests of square or rectangular cross section that, as the name suggests, are oriented across the weld so that both parent metals, both heat affected zones (HAZs) and the weld metal itself are tested (Fig.1). The excess weld metal in the cap of the weld may be left in-situ or machined off.

|

| Fig.1. Square or rectangular cross joint tensile test piece |

While it is possible to measure the yield strength, the elongation and the reduction of area of CJ specimens the fact that there are at least three different areas with dissimilar mechanical properties makes such measurements inaccurate and unreliable, although this is sometimes carried out purely for information purposes.

The specifications mentioned above require the UTS and the position of the fracture only to be recorded. The cross joint strength is usually required to exceed the minimum specified UTS of the parent metal. In most situations the weld metal is stronger than the parent metal - it is overmatched - so that failure occurs in the parent metal or the HAZ at a stress above the specified minimum.

In cases where the weld and/or the HAZs are weaker than the parent metal - welded age-hardened or cold worked aluminium alloys are a good example - this is covered in most specifications. Refer to Table 2 of BS EN 288 Part 4 or clause QW153 in ASME IX. The designer must also take this into account in design calculations and provide some method of compensating for this loss of strength.

The tensile testing of flat plate butt welds presents few problems of specimen shape but those machined from a pipe butt joint are not flat and this curvature can affect the results. In the context of welding procedure approval testing, this is not significant since the test is used only for the determination of the UTS and the position of the fracture. For more accurate results the test piece may be waisted and may be machined flat as illustrated in Fig.2.

|

| Fig.2. Flat cross joint tensile specimen machined from tube |

It may be necessary to machine a number of specimens through the thickness of a weld, particularly on very thick joints where the capacity of the tensile machine is insufficient to pull a full thickness specimen, Fig.3.

To test a small diameter tube, a solid bar is inserted in the bore of the tube to prevent the tube collapsing when the sample is clamped into the tensile machine.

Most weld testing is carried out with CJ specimens but longitudinally oriented specimens are useful particularly where the weld metal or the HAZ is very strong but ductility is low. In a CJ specimen the parent metal can yield and finally fail without the weld metal or the HAZ experiencing any significant amount of deformation whereas in a longitudinal test piece the load is shared more equally.

A brittle weld or HAZ will not elongate with the parent metal but will crack, with the cracks opening, but not necessarily propagating into the parent metal, as testing proceeds.

The testing described above is that required by the welding procedure approval specifications. These provide no assurance that the welds in a structure will be suitable for their purpose such as elevated or cryogenic service and many application standards such as BS PD 5500 Unfired Pressure Vessels, and ASME VIII Pressure Vessels, require additional tests.

Since the strength of a metal falls as the temperature rises these specifications require elevated temperature tensile tests to be carried out at the maximum design temperature.

These tests are required to be carried out on the weld metal only and use a longitudinally orientated round cross section specimen from which an accurate measurement of the proof strength can be obtained.

Many application standards such as BS PD 5500 require tests additional to those required by, for example, BS EN 288 Part 3. This must be remembered when procedure approval documentation is submitted for approval by the inspecting authority or the client.

Validity of tensile data.

The samples taken are assumed to be representative of the bulk of the material but this is not always the case.

Tensile strength of a casting, for instance, is often determined from a specimen machined from a riser and this will have a grain size different from that of the bulk of the casting.

A rolled steel plate will be found to have different properties in the longitudinal, transverse and through thickness directions. Material specifications such as BS EN 10028, Flat Products in Steel for Pressure Purposes, therefore, require the tensile test to be taken transverse to the rolling direction so that the steel is tested across the 'grain' - the lower strength, lower ductility direction.

The size of a product can also influence the properties as, during heat treatment, the section thickness will affect the cooling rate with slower cooling rates, and hence softer structures, at the centre of thicker sections. This is dealt with in material standards by specifying what is known as the 'limiting ruling section', the maximum diameter of bar at which the required mechanical properties can be achieved at the centre.

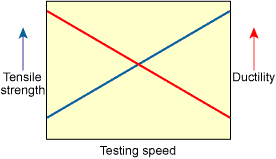

In addition to variations of the properties due to the shape of the specimens and the testing temperature, the rate of loading will also affect the results.

Figure 4 shows how the tensile strength increases but ductility decreases as the testing speed is increased. The speed of the cross head of the tensile machine therefore needs to be controlled and BS EN 10002 specifies a stress rate range of 6MPa per second to 60MPa per second. The ASTM specifications have similar - but not identical - requirements.

|

| Fig.4. Effect of speed of testing on strength and ductility |

Needless to say, calibration of testing equipment to guarantee operation within acceptable parameters is mandatory.

Relevant specifications

BS EN 10002 Methods of tensile testing of metallic materials.

BS EN 876 Destructive tests on welds in metallic materials - longitudinal tensile test.

BS EN 895 Destructive tests on welds in metallic materials - transverse tensile test.

BS EN ISO 7500-1 Tension/compression testing machines. verification and calibration of the force measuring system.

ASTM A370 Mechanical testing of steel products.

ASTM E8 Tension testing of metallic materials.

ASTM B557 Tension testing wrought and cast aluminium and magnesium alloy products.

Dust test chamber is used to perform dust test and to test the functioning of the components under different climatic conditions. The test duration and the actual composition of the dust will be indicated.

ReplyDelete